Share This Article

The vehicle distributor is an often disregarded yet essential factor inside the ignition machine of many older cars. This critical element ensures the right functioning of the engine by directing electric current to the appropriate spark plugs at the right time. In this comprehensive guide, we will explore what the vehicle distributor is, how it works, and how you may perceive and fasten unusual distributor troubles to maintain your automobile jogging easily.

Whether you are an experienced automobile proprietor or a first-time DIY mechanic, this article will give you all the tools you need to apprehend, preserve, and troubleshoot your distributor. So allow’s dive in!

Understanding the Role of a Car Distributor in Your Vehicle’s Ignition System

In older cars that use a conventional ignition machine, the distributor is on the coronary heart of the ignition system. Its primary process is to direct high-voltage electrical present-day from the ignition coil to the proper spark plug at the proper second required for combustion.

The Basics of the Distributor

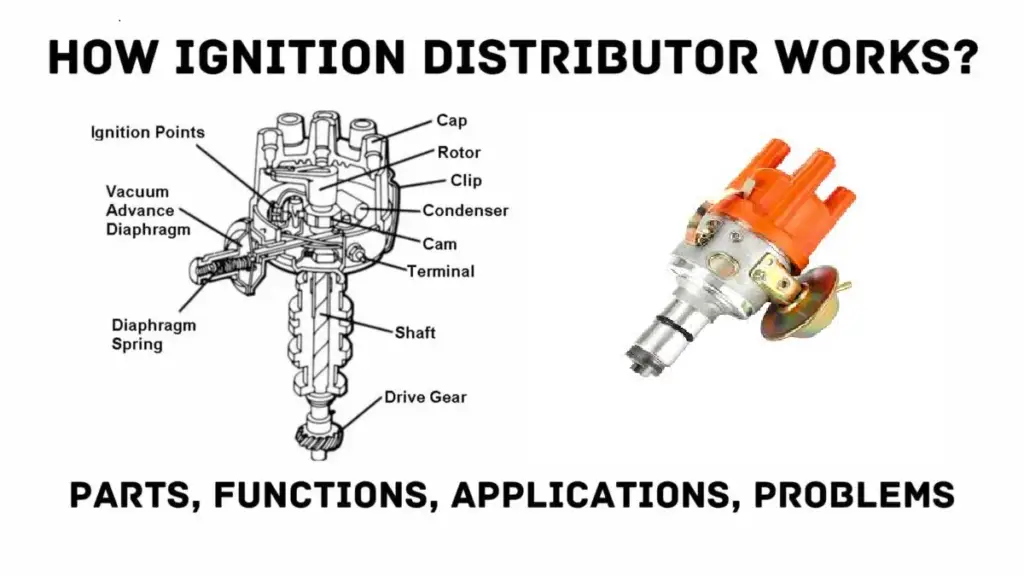

The distributor consists of several additives that paint together to make certain the engine runs easily. Here’s an outline of these components:

- Distributor Cap: Houses the spark plug wires.

- Rotor: Rotates in the cap to transfer electrical modern to the spark plugs.

- Points (In Older Models): Act as a switch to permit electric modern-day to flow at the right time.

- Vacuum Advance: Adjusts the ignition timing based on engine load for advanced overall performance and gasoline performance.

When the engine is walking, the rotor spins within the distributor cap and sends electrical modern-day to the proper spark plug, ensuring that each cylinder fires in the correct order. Without a functioning distributor, the engine could struggle to start and run nicely, main to overall performance problems and probably engine failure.

Why the Car Distributor Is Important for Engine Performance

The distributor performs a crucial role in retaining the choicest engine performance. It is a key player inside the ignition machine that affects:

- Power Generation: Proper ignition timing ensures that the engine generates energy efficiently.

- Fuel Efficiency: Misfires because of a defective distributor can cause a terrible gas economy.

- Engine Longevity: A well-maintained distributor prevents engine damage with the aid of making sure easy operation.

Without a functioning distributor, the engine wouldn’t be capable of igniting the air-gas aggregate at the right moment, which might result in poor performance, misfires, and different mechanical problems.

Common Car Distributor Problems and How to Identify Them

Over time, your distributor can also broaden issues that could have an effect on engine performance. Understanding the commonplace issues that arise can help you address them before they cause the most important harm.

1. Worn or Cracked Distributor Cap and Rotor

One of the most common issues with the car distributor is a worn or cracked distributor cap and rotor. These components are exposed to high temperatures and electric currents, that could cause them to go to pot over time.

Symptoms of a Worn or Cracked Distributor Cap and Rotor:

- Engine misfires: When the distributor cap is cracked or the rotor is worn, electrical arcing can arise, causing the engine to misfire.

- Difficulty beginning the engine: A malfunctioning distributor cap or rotor can cause trouble with ignition, making it tougher for your automobile to start.

- Backfiring: A bad distributor can result in fuel aggregate issues, resulting in engine backfires.

How to Fix:

To restore a damaged distributor cap and rotor, visually look into the components for cracks, corrosion, or signs of wear. If you notice any harm, replace the components with new ones. Be certain to apply amazing additives to ensure reliable performance.

2. Faulty Distributor Points (In Older Vehicles)

In older cars that use mechanical distributor factors, these parts can be put out over time, inflicting terrible overall performance. The factors manage the electrical current flowing into the rotor and want to hold the appropriate gap to work well.

Symptoms of Faulty Distributor Points:

- Rough idle: If the distributor factors are worn, the engine may additionally idle kind of.

- Stalling: The engine can also stall unexpectedly due to unsuitable timing resulting from faulty points.

- Difficulty beginning: A worn factor can cause delayed or unreliable starting.

How to Fix:

To deal with issues with distributor points, you can clean them with a touch cleanser and use a feeler gauge to adjust the space. If the factors are too worn or damaged, it’s excellent to update them with new ones.

3. Broken or Worn Vacuum Advance

The vacuum advance is responsible for adjusting the ignition timing based totally on engine load and velocity. If the vacuum strength fails, the timing will remain constant, main to bad engine performance and knocking.

Symptoms of a Faulty Vacuum Advance:

- Poor acceleration: Without proper timing adjustments, the engine will battle to boost up easily.

- Knocking: A malfunctioning vacuum strength can motivate the engine to knock or ping all through acceleration.

How to Fix:

Use a vacuum pump to test the vacuum advance. If it doesn’t preserve the vacuum, it’s time to replace the aspect. Ensure that the brand-new vacuum development is nicely calibrated for your automobile’s specs.

4. Worn Distributor Shaft

The distributor shaft connects to the camshaft and drives the rotor. Over time, it may be put down, main to timing troubles and negative engine overall performance.

Symptoms of a Worn Distributor Shaft:

- Erratic engine behavior: If the distributor shaft is worn, the timing may be unpredictable, main to poor engine conduct.

- Difficulty preserving idle speed: The engine may additionally battle to maintain a constant idle velocity.

How to Fix:

If the distributor shaft is excessively worn, you’ll need to replace the entire distributor unit. Replacing the entire distributor ensures that each component is working well, enhancing engine’s overall performance.

How to Maintain Your Car Distributor for Optimal Performance

Regular renovation is prime to ensuring that your distributor continues to function nicely. Keeping it in appropriate shape lets you keep away from high-priced upkeep and prevent engine overall performance issues.

1. Inspect the Distributor Cap and Rotor Regularly

Since the distributor cap and rotor are uncovered to put on, it’s essential to look into them frequently. Look for cracks, corrosion, or buildup of debris. If you work any problems, update them right away.

2. Check Ignition Timing Periodically

Even in case your distributor is functioning properly, checking the ignition timing every few months can help ensure the most excellent engine performance. A moderate deviation in timing can negatively affect gas efficiency and electricity output.

3. Replace Worn Parts Promptly

If any aspect of the distributor is worn or broken, update it as quickly as feasible. Keeping your distributor in top condition will help your engine run greater successfully and prevent larger issues down the road.

How to Replace a Faulty Car Distributor

If your distributor is beyond restoration, changing it can be important. Here’s a step-with the aid of-step guide to replacing your car distributor:

Tools Needed:

- Wrench set

- Screwdriver

- Timing mild

- New distributor (specific for your car version)

Steps:

- Disconnect the Battery: Always disconnect the battery to keep away from any electrical injuries whilst operating on the distributor.

- Remove the Distributor Cap: Unscrew the distributor cap and put off it to get the right of entry to the rotor and factors.

- Mark the Timing Position: Before casting off the distributor, mark its role on the engine to ensure the right alignment at some stage in reinstallation.

- Remove the Old Distributor: Unscrew the distributor and carefully put off it from its housing.

- Install the New Distributor: Position the new distributor inside the same location as the vintage one, aligning it with the timing marks you made earlier.

- Reattach the Cap and Wires: Once the distributor is in the region, reattach the distributor cap and the ignition wires.

- Check and Adjust Timing: Use a timing light to check the ignition timing and modify it if vital.

- Reconnect the Battery and Test: After reconnecting the battery, begin the engine and make sure the whole lot runs easily.

Conclusion: The Importance of a Functional Car Distributor in Engine Performance

While the car distributor may also appear like a small and unimportant part of your engine, it performs a chief position in ensuring that your automobile runs correctly. Properly maintained, a distributor can assist your engine obtain top overall performance, prevent misfires, and improve the gas financial system.

By knowing how the distributor works and understanding the way to spot common problems, you can keep your automobile jogging easily for years yet to come. Regular renovation, well-timed upkeep, and spark-off alternatives of worn elements will make certain that your distributor maintains its vital position for your engine.

Remember, the distributor won’t be as glamorous because of the engine or transmission, however, without it, your car wouldn’t be capable of features at all. So, supply it with the eye it deserves, and it will reward you with years of reliable service.

FAQs

1. What is the motive of a vehicle distributor?

The car distributor is a vital factor of a vehicle’s ignition gadget, typically chargeable for directing the electric present-day from the ignition coil to the ideal spark plug at the correct moment required for combustion. This ensures the engine fires nicely, permitting the car to run smoothly and efficaciously.

2. How do I know if my automobile distributor is defective?

Common signs of a faulty distributor include:

- Engine misfires or difficult idling

- Difficulty starting the engine or stalling

- Backfiring or hesitation during acceleration

- Poor acceleration or knocking sounds

If you know any of those signs and symptoms, it’s an excellent idea to investigate your distributor for harm or put on.

3. How frequently should I update the distributor cap and rotor?

It’s recommended to inspect the distributor cap and rotor each 20,000 to 30,000 miles, or as per your vehicle producer’s pointers. If there are signs of cracks, wear, or corrosion, you ought to replace them quickly to prevent ignition problems.

4. Can I restore a defective distributor or should I replace it?

Minor issues, inclusive of worn distributor points or a broken distributor cap, can be repaired or replaced for my part. However, if the distributor shaft or the entire unit is significantly worn or broken, it is able to be essential to replace the entire distributor to repair the engine’s overall performance.

5. How can I check the ignition timing on my distributor?

You can check the ignition timing using a timing mild. First, connect the timing mild to the battery and spark plug twine. Then, start the engine and factor the timing light on the timing marks at the engine. If the timing is off, you could alter the distributor to bring it lower back into the producer’s certain variety.