Share This Article

What is valve clearance?

Introduction

Engine performance is important for the smooth jogging of any car, and one of the key factors that make a contribution to its performance is engine valve upkeep. One essential element of engine health is the adjustment and right functioning of the gap between the engine’s valves and their corresponding additives. This area, frequently mentioned in technical phrases, plays a huge position in regulating the air-gas combination and exhaust gases, ensuring that the engine operates efficiently.

Many automobile and bike proprietors won’t be familiar with the idea of valve adjustment, but information on this component of your engine can help you keep away from needless maintenance and expand its lifespan. Proper clearance among the engine valves leads to the most efficient engine performance, decreasing the chance of problems such as misfiring, overheating, or negative gas efficiency. Ensuring an appropriate hole also enables you unnecessary wear and tear on engine components, ultimately saving you time and cash on upkeep.

In this article, we will discover what valve clearance is, why it topics for your engine, and how you can maintain it efficiently. By the end of this guide, you may have a clear understanding of this often-omitted element of engine maintenance and a way to keep your automobile jogging smoothly for future years. Whether you’re a beginner or skilled in car protection, this understanding can contribute to higher engine care and overall car performance.

1. What is Valve Clearance?

In an inner combustion engine, particular coordination among various additives is crucial for smooth performance, and one such critical factor is the gap between the engine’s valves and the corresponding mechanical components, which include the lifters or rocker’s arms. This gap, regularly known as valve clearance, guarantees that the engine’s valves are open and near at the precise time, taking into consideration efficient air consumption and exhaust expulsion.

This small however important hole helps atone for thermal enlargement inside the engine’s components as they heat up for the duration of operation. As the engine runs, the steel elements expand, and the clearance adjusts hence to keep proper valve timing. Without this clearance, valves ought to fail to shut absolutely, main to loss of compression or inefficient combustion, or they may remain too open, causing damage to engine additives.

Understanding this simple but large thing of engine layout is critical for vehicle proprietors and mechanics alike. Maintaining the right distance among these shifting parts guarantees your engine runs successfully, plays optimally, and avoids costly maintenance. Regular assessments and changes of this space are a key part of engine maintenance and can substantially affect the durability and usual performance of your car.

2. Why is Valve Clearance Important?

The right adjustment of the space among engine valves and their additives performs an important function in retaining optimum engine overall performance. When the distance is effectively set, it allows the valves to open and close at the proper times, making sure of green gas combustion and proper exhaust expulsion. This results in stepped-forward engine efficiency, a better gasoline economic system, and enhanced ordinary performance.

If the space is just too small, the valves might not be completely near, main to a lack of compression and engine misfires. On the other hand, if the gap is too big, it could cause immoderate wear on engine components, leading to inefficient operation and potentially expensive upkeep. In either case, unsuitable valve clearance can have an effect on the timing and functioning of essential engine structures, ultimately impacting the sturdiness and overall performance of the automobile.

Regular monitoring and adjustment of this important area are crucial to keep away from engine problems inclusive of overheating, negative acceleration, and extended emissions. By ensuring the appropriate hole, car proprietors can experience smoother rides, accelerated engine sturdiness, and reduced restoration costs. Maintaining proper valve features isn’t pretty much maintaining overall performance—it’s also approximately shielding your engine’s fitness ultimately.

3. How Valve Clearance Works

In an engine, the valves play a vital function in regulating the waft of air and exhaust gases. To function nicely, these valves need to open and near at particular periods during every cycle of the engine. The gap between the valve and its associated issue (like the lifter or rocker’s arm) enables control of the timing and motion of those valves.

When an engine operates, the elements become bigger due to heat, which could have an effect on their function and functioning. This is where the space among the components becomes essential. By maintaining the right amount of area, the valves can circulate freely without inflicting damage or hindering overall performance. When the engine heats up, this area accommodates the thermal expansion of metal elements, stopping the valves from sticking or failing to close absolutely.

The hole additionally guarantees that the engine valves do not live in contact with different engine additives in the course of operation, which could lead to immoderate wear or even everlasting harm. Proper clearance ensures that each valve opens and closes on the surest second, taking into account the efficient intake of air and exhaust of gases, which is key to maintaining engine strength, gasoline performance, and sturdiness.

4. How to Check Valve Clearance

Checking the space among the engine valves and their corresponding components is a crucial preservation mission that guarantees your engine operates efficiently. The manner calls for cautious interest and particular equipment to avoid unfavorable engine elements. Here’s a simple manual that will help you through the system:

1. Gather Necessary Tools

You will need a fixed of feeler gauges, a wrench set, and a socket to remove any engine covers. It’s also encouraged to have the automobile’s provider manual on hand because the specs for valve gap measurements vary by using make and model.

2. Remove Engine Components

Start by way of doing away with the valve cowl or different elements obstructing access to the engine valves. This might require using a wrench or socket to undo bolts. Be positive to observe the producer’s commands to keep away from detrimental any components.

3. Find the Correct Measurement

Consult your automobile’s provider guide to decide the right clearance specification for your engine. This dimension can vary, so it is essential to consult the manual for correct information.

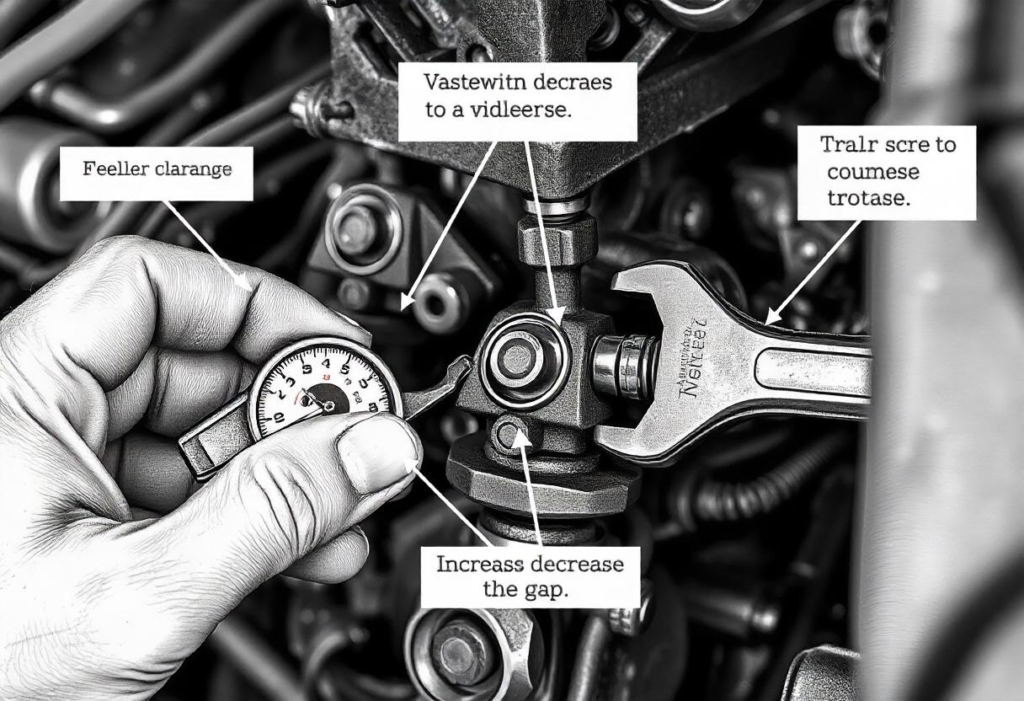

4. Use Feeler Gauges

Place a feeler gauge between the valve and its factor to measure the distance. Start with the smallest length and work your way up until you discover the correct thickness that fits snugly and permits mild motion. Repeat this step for all valves.

5. Adjust if Necessary

If the space is just too wide or too slender, you’ll want to adjust it by loosening the related components and moving them until the right size is done. This would possibly contain adjusting the rocker fingers, shims, or other associated elements.

6. Reassemble the Engine

Once all of the valves are nicely measured and changed, reassemble the engine components cautiously. Replace the valve cover and make certain all bolts are securely tightened.

Checking the clearance among the engine valves is a sincere system however calls for precision. Regular tests assist save you from performance issues, improve gas performance, and defend your engine from needless damage.

5. Common Valve Clearance Issues

When the gap among engine additives isn’t always well set, it could result in quite a few engine overall performance issues. Identifying and addressing those common troubles early can prevent pricey upkeep and make certain your engine runs easily. Here are some of the most frequent troubles associated with flawed valve adjustment:

1. Insufficient Gap (Too Tight)

If the gap is too slim, the valves might also fail to be fully near, main to poor compression and engine misfires. This can result in a substantial loss of power, rough idling, and poor gas efficiency. In intense instances, it may cause engine overheating as the valves fail to properly expel exhaust gases, putting extra strain on the engine.

2. Excessive Gap (Too Loose)

When the space is just too extensive, the valves may not make the right contact with the rocker arm or other components, leading to immoderate noise and inefficient operation. This can also cause uneven valve timing, affecting the consumption of air and the exhaust of gases. Over time, this may result in immoderate put on the valve components, causing them to degrade quicker than regular.

3. Irregular Valve Function

In some cases, inconsistent valve features can arise whilst the valve clearance is inconsistent across exceptional valves. This can result in choppy engine overall performance, along with some cylinders running warmer than others or inefficient combustion. It can also make a contribution to difficult acceleration and a lower in common engine electricity.

4. Premature Wear and Tear

A wrong hole can cause premature wear on engine components like rocker hands, lifters, and valve publications. If left unaddressed, this may cause high-priced harm to critical engine elements, doubtlessly requiring a whole overhaul. Regular assessments and modifications can help prevent this kind of deterioration.

Recognizing and addressing these issues early can help keep your engine’s efficiency, lessen restore prices, and ensure lengthy-time period reliability. Regular renovation and proper changes are key to stopping commonplace valve-associated issues.

6. How to Adjust Valve Clearance

Adjusting the space between the engine valves and their components is an essential step in preserving engine health and overall performance. While the method may additionally range barely depending on the car’s make and model, right here’s a fashionable manual to help you alter the distance successfully:

1. Gather the Right Tools

Before starting, make sure you’ve got the essential equipment, such as a feeler gauge set, a wrench, and possibly a shim package (in case your car requires shims for changes). Always seek advice from your car’s carrier manual for the particular equipment and procedures

wished.

2. Remove the Valve Cover

To get right of entry to the engine valves, you’ll need to get rid of the valve cover or any components blocking the region. Use a wrench or socket set to cautiously remove the bolts, and set the elements apart in a safe location. Make positive to easy the surfaces before

reassembling later.

3. Set the Engine to Top Dead Center (TDC)

Before making any changes, ensure the engine is on the Top Dead Center of its compression stroke. This will ensure all of the valves are in the proper function for measuring and adjusting. You can try this by turning the crankshaft manually at the same time as observing the timing marks.

4. Measure the Gap

Using a feeler gauge, measure the gap between the valve and the rocker arm or lifter. Insert the gauge among the elements, starting with the smallest size, and paint your manner up till you find the right size. Refer for your automobile’s guide for the exact specifications, as they can vary depending on the engine type.

5. Adjust the Gap

If the space is simply too wide or too slender, changes are wanted. You can adjust the space by loosening the adjusting nut at the rocker’s arm and turning the screw or bolt that controls the valve function. Once you obtain the desired hole, tighten the nut and recheck the measurement to make certain accuracy.

6. Repeat for All Valves

Repeat the process for every valve within the engine, making sure you degree and modify each one in keeping with the specs. Be sure to test and recheck all of the settings earlier than proceeding to the following step.

7. Reassemble the Engine

Once all changes are made, carefully update the valve cover and every other component that has been removed. Tighten all bolts securely, and make sure there are no leftover elements before remaining the entirety up.

Adjusting the distance among engine components is an in-depth system, however, with the right equipment and technique, you may significantly enhance your engine’s efficiency, prevent immoderate wear, and ensure smoother operation. Regular modifications, as endorsed through your vehicle’s carrier manual, will help hold long-time period engine fitness.

7. Valve Clearance in Different Engines

The gap among engine additives performs a crucial function in ensuring smooth engine operation, but the specifics of this adjustment can vary depending on the sort of engine. Understanding how clearance is handled in distinctive engines allows you to well maintain your automobile or machinery. Here’s a top-level view of how valve changes range across numerous engine kinds:

1. Automotive Engines

In most present-day automotive engines, valve gaps are carefully set to ensure optimum gasoline efficiency, easy idling, and right exhaust expulsion. These engines frequently use hydraulic lifters, which mechanically regulate the distance as the engine operates, making guide adjustments much less unusual. However, some older models, particularly those with mechanical lifters, may also require periodic checking and manual adjustment to maintain overall performance.

Automotive engines typically have tighter clearance specifications than large engines, as they operate at higher revolutions according to minute (RPM). For most automobile owners, it’s encouraged to observe the manufacturer’s protection agenda for valve exams to ensure regular engine performance.

2. Motorcycle Engines

Motorcycle engines, particularly those with overhead camshafts, often require extra frequent assessments and changes of the gap among components. Unlike vehicle engines, many motorcycles have mechanical lifters that don’t routinely atone for changes in temperature and wear. This means manual changes are frequently vital to maintain the right engine performance.

Motorcycle engines may have one-of-a-kind clearance necessities depending on their kind (e.g., unmarried-cylinder vs. Multi-cylinder) and the materials used in the engine. Regular assessments are essential to save you performance troubles consisting of difficult idling, misfires, or engine harm.

3. Diesel Engines

Diesel engines, normally determined in vans, business machinery, and larger motors, frequently have exceptional valve adjustment needs in comparison to gas engines. Diesel engines usually use solid lifters that require guide changes. The clearance is generally large in diesel engines due to their higher compression ratios and the elevated pressure within the combustion chamber.

Routine tests and changes are important for diesel engines to make sure they hold to run efficaciously, especially due to the fact they operate beneath greater severe conditions as compared to smaller gasoline-powered engines. Diesel engine valve changes are regularly performed at longer periods, but they need not be overlooked.

4. Small Engines (e.g., Lawn Mowers, Generators)

Small engines, along with the ones in garden mowers or transportable generators, typically have an extra sincere design. These engines frequently function in less difficult valve configurations and are designed for less difficult maintenance. Although they may now not require frequent modifications, ensuring the right clearance can assist prevent starting problems, hard walking, or poor fuel efficiency.

In these engines, valve adjustment is usually a easy process, however the frequency can vary relying on the manufacturer’s tips. It’s critical to test the valve space at everyday intervals to keep away from needless put on and tear.

5. Performance Engines

Engines built for excessive-overall performance motors or racing situations may require specialized valve modifications due to the extreme working situations they face. These engines frequently have tighter tolerances and more specific specs, making normal valve checks and adjustments essential. High-overall performance engines can also use adjustable rocker arms or different additives that permit great tuning of the valve gap to optimize overall performance at extraordinary RPMs.

For excessive performance or racing engines, regular renovation and adjustments are crucial to attaining the most strength output and stopping untimely engines.

8. Signs Your Valve Clearance Needs Attention

Properly adjusted gaps among engine additives are crucial for the easy operation of any engine. When this space becomes too extensive or too slender, numerous signs may also rise up, indicating that the adjustment wishes interest. Here are a few commonplace signs to look out for:

1. Engine Misfires or Rough Idle

One of the most substantive signs that the space among the engine’s components is off is engine misfiring or tough idling. If the valves fail to open or close properly due to incorrect spacing, it can cause a disruption within the combustion procedure. This results in choppy engine overall performance, especially in the course of idle while the engine is walking at low RPMs.

2. Loss of Engine Power

If the distance is just too tight or too free, it can save the valves from working at their most beneficial timing. This effects in a discount on engine electricity, in particular, while accelerating. If you note a decrease in acceleration or your engine feels gradual, flawed valve adjustment can be the cause.

3. Increased Fuel Consumption

An engine with improper valve clearance may additionally fail to burn fuel correctly, leading to a boom in fuel intake. If your automobile or system of suddenly starts ingesting more fuel than regular, this will be a sign that the components aren’t functioning as they need to, affecting the performance of combustion and air-gas mixture intake.

4. Unusual Engine Noises

Excessive valve noise, including ticking or tapping sounds, often indicates a difficulty with the valve spacing. If the gap is just too huge, the valves may additionally create excessive noise when they make contact with the rocker fingers or lifters. On the other hand, a completely tight gap can cause components to stay in steady touch, resulting in a grinding noise.

5. Difficulty Starting the Engine

An engine with incorrect clearance may additionally display trouble starting. If the valves aren’t closing nicely, it is able to lead to terrible compression, making it more difficult for the engine to show over. This can bring about lengthy cranking times or entire failure to start.

6. Poor Acceleration or Hesitation

If your engine hesitates or stutters when you try to boost up, it may be due to incorrect valve timing. The gap among engine components can have an effect on how efficaciously the engine intakes air and expels exhaust, which results in hesitation or jerking for the duration of acceleration.

7. Overheating

Incorrect valve spacing also can contribute to engine overheating. If the valves aren’t establishing or closing completely, the combustion system won’t be efficient, causing excess warmth to build up inside the engine. If you observe your engine running warmer than normal, a valve adjustment can be wished.

8. Check Engine Light

In contemporary automobiles, a malfunction inside the valve operation might also trigger the take a look at engine light. The engine management unit (ECU) may discover irregularities in overall performance and signal that some thing is wrong, which includes troubles with valve timing or compression because of incorrect spacing.

9. When Should Valve Clearance Be Checked or Adjusted?

Regularly checking and adjusting the gap between engine additives is crucial to preserving the engine’s overall performance and longevity. While the frequency of those tests can vary depending on the sort of engine and the producer’s guidelines, there are positive times when you have to prioritize this upkeep undertaking.

1. Manufacturer’s Recommended Intervals

The first and most vital guideline is to comply with the durations specified in your car or engine’s provider manual. Manufacturers regularly offer a preservation schedule that outlines when valve exams ought to arise. This is commonly based totally on mileage, hours of operation, or engine age, and serves as a great reference for when to timetable inspections.

2. After Significant Engine Work

If you’ve had predominant engine maintenance, which includes head gasket alternative or valve-associated repairs, it’s vital to test the valve spacing after reassembly. Any time the engine has been disassembled or elements have been replaced, it’s clever to make sure everything is nicely adjusted to prevent any lengthy-term damage or performance troubles.

3. Performance Issues

If you note any symptoms of engine performance troubles—such as hard idling, misfires, lack of power, or unusual engine noises—this will suggest that the valve spacing is off. In such cases, it’s critical to check the space among components to see if an adjustment is needed. Ignoring performance problems should cause additional harm, so addressing them directly is prime.

4. High-Performance or Racing Engines

Engines used in excessive performance or racing packages frequently require greater frequent checks and adjustments. These engines are subjected to higher stress, which could cause components to put on more fast. For high-RPM engines, it’s not unusual to check the valve gap more regularly, as unique valve timing plays a main role in common engine performance.

5. Regular Maintenance for Older Engines

For older cars or machinery, it’s a great practice to inspect and modify the valve gap at normal intervals, even though performance problems haven’t been determined. As engines age, valves put on can result in modifications in the required clearance, so normal checks assist hold engine performance and save you capacity problems.

6. After Overheating Incidents

If your engine has overheated, it’s essential to test the space between the additives as overheating can purpose components to expand and shift. This can affect the timing and operation of the valves, so performing a check after overheating guarantees the entirety is functioning as it has to.

7. Environmental Factors

In positive environments, together with high-altitude areas or extreme temperatures, valve clearance may alternate extra swiftly due to the outcomes of temperature or atmospheric stress. In such instances, more common checks can be vital to make sure the engine maintains to perform optimally under varying situations.

Conclusion

Maintaining the best gap between engine components is an important part of making sure your engine operates efficiently and reliably. Whether you are operating with an automobile engine, bike, or industrial equipment, information on how and while to check and modify these gaps can prevent high-priced maintenance and enhance universal engine performance.

By regularly tracking and adjusting the space among the valves and their corresponding parts, you can keep away from issues that include engine misfires, negative fuel performance, and excessive put-on. Always observe the producer’s recommended maintenance agenda, however, consider the signs and symptoms that suggest your engine may additionally need attention. If you observe symptoms like rough idling, unusual noises, or strength loss, it’s time to test and regulate the valve spacing.

With the right gear, a bit of information, and proper preservation, you can maintain your engine running smoothly for years yet to come. Regularly addressing those changes will not handiest beautify overall performance but also make bigger the life of your engine, ensuring it continues to supply the most useful energy and efficiency.

FAQs

1. What happens if valve clearance is simply too tight?

If the space among engine components is too slender, the valves might not be completely near. This can cause terrible compression, misfires, and hard idling. It may also cause excessive engine warmth, as exhaust gases are not nicely expelled, main to potential overheating and increased engine pressure. In the long run, this can lessen engine performance or even motive severe damage if left unaddressed.

2. Can valve clearance be adjusted by myself?

Yes, you could regulate the valve spacing yourself, furnished you have the proper tools and knowledge. You will need a feeler gauge set, wrenches, and probably a provider guide for your automobile or engine. However, it’s crucial to follow the ideal strategies cautiously to avoid destroying the engine. If you are no longer snug in this assignment, it’s first-rate to seek advice from a professional mechanic.

3. How do I realize that my car desires valve clearance adjustment?

Signs that your engine may want a valve clearance adjustment include rough idling, engine misfires, loss of strength, uncommon engine noises (including ticking or tapping), and problems starting the engine. If you revel in any of these symptoms, it’s crucial to test the valve spacing and make modifications as desired.

4. What causes valve clearance to exchange through the years?

Valve clearance can alternate due to everyday engine wear and tear. As the engine additives age, the valves, valve seats, and different elements may also be put down, causing the distance between them to grow or decrease. Heat cycles, temperature fluctuations, and the working situations of the engine also contribute to modifications in valve clearance over time.

5. What are the symptoms of horrific valve clearance?

Symptoms of flawed valve spacing consist of terrible engine overall performance, including tough idling, misfires, hesitation all through acceleration, and unusual engine noises like ticking or tapping. You may additionally observe a boom in gas consumption or engine overheating. Addressing these signs early can assist save you ffrom urther damage to the engine.